Metso has launched the HPGRSense™ solution for optimizing grindingefficiency through accurate monitoring of its HRC™e high-pressure grindingrolls (HPGR). Unique to the market, the HPGRSense™ is a stand-alone systemthat provides continuous simultaneous monitoring of the rolls, eliminating theneed to stop the process for inspections.

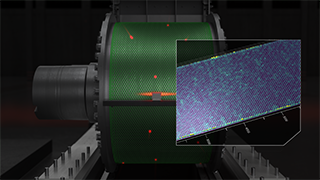

“HPGRSense™ is transforming roll inspection and wear measurement onHPGR rolls while avoiding the limitations of existing laser-basedsolutions. HPGRSense™ safely and remotely gives operators full visibilityto the rolls’ condition during operation, thereby increasing theirunderstanding of the rolls’ state. The scanning device uses an array of sensorsto inspect the roll surface and, in combination with advanced analytics,to detect anomalies and measure wear. This empowers operators to respondquickly to roll damage, predict service life and maximize efficiency of sparestock holding. With this greater understanding, operators can maintain maximumproductivity of their HRCe,” says Stefan Sakendorf, Director, HRC at Metso.

Cutting-edge HPGR technology foroptimized processes

Metso launched the HRC™ high-pressure grinding rolls for comminutioncircuits in mineral processing plants in 2014, setting an industry standard forHPGR solutions. Not only known for its improvement in energy efficiency,extended wear life and increased throughput, this innovation also pioneered theindustry acceptance of flanges as superior grinding technology. Metso HRC™e –the latest evolution – provides the same benefits in wear, circulating load andpower consumption while improving the layout and serviceability.

The HPGRSense™ monitoring solution takes the HRC™e HPGR to a new level byproviding safe, remote, real-time insights and predictive maintenancecapabilities, ensuring optimal performance and longevity of the grinding rolls.