Lack of digitalization isone of the major reasons for inefficiencies in construction. However, moderntechnology solutions available today allow project owners and managers todigitalize the entire construction workflow and automate several processes,thus minimizing human errors in the design-to-detail stage allowing projectowners to exercise full control over a project’s costs and timelines, says Harsh Pareek.

“Inefficiencies willpersist as long as all stakeholders continue to work in silos with no digitalflow of information among them. The only way to remove them is to take the helpof process digitalization and automation, which will ensure that all thestakeholders are always in sync with each other and have access to the latestand most updated project-related information.”

Wouldyou highlight the importance of minimizing human errors in design-to-detailstages?

Construction projects canbe very complex to execute, as they have multiple teams and stakeholdersworking simultaneously onsite and offsite with many interdependencies. On anygiven project, project managers need to work closely with structural engineers,who in turn must work closely with designers and architects. Further, they needto collaborate with fabricators and contractors. Given the huge budgetsinvolved and the time constraints, these teams must work in sync, as one team’swork has a direct impact on the other.

The optimal projectexecution demands that the work done by individual teams or stakeholders iserror-free, and there are no mistakes in the flow of the latest information orupdates from one team to another. We have also seen how in the absence ofseamless flow of information, a single human error can easily snowball and leadto an escalation in costs for the project, besides causing time delays. Often,an entire finished portion has to be demolished and rebuilt, or there aremultiple RFIs to the engineering team, either of which inevitably delays theproject.

Large constructionprojects, in particular, involve a lot of data that must be seamlesslytransferred from one team to another in real-time. In the absence of astandardized, foolproof communication process, there is always a highprobability that either partial or old and incorrect information is sharedamong stakeholders.

These types ofcommunication errors also end up costing a lot of time and money to rectify. Therefore,project owners need to minimize all human errors in the design-to-detail stageto exercise full control over a project’s costs and timelines.

So,are you saying that existing processes in site analysis and work scheduling areinefficient?

Like we discussed a whileago, the construction process – from design to finish – involves many teams andstakeholders, all of whom depend on one another and, thus, need to work intandem. Traditionally, many of the important construction tasks – from siteanalysis to work scheduling or even modelling – were done manually, which meanta high probability of human errors and mistakes. The modern connected constructionprocess uses fully digitalized workflows where the software prevents theoccurrence of human errors to a large extent and, thus, helps maximize theproject team’s efficiencies.

Lack of digitalization isone of the major reasons for the inefficiency. Usually, designers work fromtheir office, while engineering teams are spread between the office and theproject site. As a result, the coordination and collaboration between the twogroups become a challenge and it becomes difficult to catch errors or reconcilediscrepancies and gaps in communication. Also, the communication of outdatedinformation is always a risk due to the lack of real-time updates.

These inefficiencies willpersist as long as all stakeholders continue to work in silos with no digital flowof information among them. The only way to remove them is to take the help ofprocess digitalization and automation, which will ensure that all thestakeholders are always in sync with each other and have access to the latestand most updated project-related information.

Howhas technology been able to improve on-site productivity and efficiency?

Modern technologysolutions available today allow project owners and managers to digitalize theentire construction workflow and automate several processes. These solutionsintegrate cutting-edge hardware with software and help reduce errors andoverlaps in construction, while simultaneously enabling better collaboration,all of which contribute to significant improvements in onsite productivity.

For example, the latestedition of Trimble’s flagship software, Tekla Structures 2021 has introducedthe ‘Tekla design-to-detail workflow’ for more efficient reinforcedcast-in-place (CIP) concrete modelling. Today, Tekla Structures provides betterways to filter and organize data in the pre-design stage to estimate the budgetand assess the scope of the project. Hence, by the time the on-site workbegins, firms can maintain a better financial and time-based control on theproject, resulting in faster and on-budget delivery of projects, and in turn,healthier project margins and improved bottom line.

Also, now we haveuser-friendly Augmented Reality (AR) tools, like Trimble’s SiteVision andTrimble’s XR10 with HoloLens 2. They allow the supervisors to visualize andexplore complex project information by juxtaposing and overlaying virtual 3Dmodels onto the actual site of construction. These tools not only bringunprecedented accuracy to a project’s execution but also lead to more efficientplanning, collaboration, and reporting workflows.

Trimble’s SiteVision evenmakes it possible to supervise and monitor a project site remotely bylive-streaming an extended reality view of a job site to anywhere in the world.

Finally, some AI-basedtools can even predict onsite accidents by analysing workers’ movements andonsite behaviour and comparing it with previous records. They can warnsupervisors that the workers are tired or negligent in following safety norms. AI-powered robots are today able to doon-site inspection and monitoring, especially in risky sections or areas of asite, thus preventing human workers from getting exposed to avoidable risks.

Howcan one achieve effective detailing and rebar designing with tech tools?

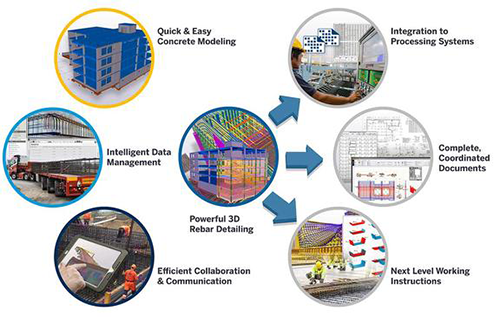

Trimble’s flagshipsoftware for building information modelling, Tekla Structures 2021 enableshighly efficient reinforcement modelling in 3D with a construction-ready levelof accuracy (LOD400). Such a high level of development in turn significantlyimproves the quality of detailed rebar design and documents.

The software furtherallows the automatic transfer of model data to production, leading to a moreeffective exchange of information among all stakeholders involved in a project.In other words, it can bring significant savings in time and money for theentire project, and further allow detailers to offer better deliverables totheir customers.

3D rebar detailing alsoensures the generation of documents with correct, consistent Information whichcan be easily adjusted and modified. One can generate placement and productiondrawings complete with bar marks, pull-out pictures, and bar bending schedulesdirectly from the 3D model and the reports automatically adapt to any changesin concrete geometry or properties like cover thickness.

Tekla Structures, whichis now available on subscription and which lowers the entry cost for softwareuser, also cuts down the detailing time of repetitive structures by usingintelligent custom components.

HarshPareek is a senior leaderwith over 22 years of experience in building and leading multicultural teams inPan-India roles. He has extensive experience working across the value chainwith a track record of building strategy, driving organizational transformation,and business turnaround. Key skills include cloud transformation, constructiontechnologies, and fostering greater agility in the digital era.

Harsh speaks and writes extensively on topicsrelated to the future of Construction and the transformative power of DigitalConstruction.

“AI-powered robots aretoday able to do on-site inspection and monitoring, especially in riskysections or areas of a site, thus preventing human workers from getting exposedto avoidable risks.”