PURTOP offers a range of Polyurea-based waterproofing membranes that can be used for both new and existing structures.

The PURTOP range is a series of continuous, two-component, polyurea-based membranes without solvents, suitable for application on various types of substrate. They may be used to waterproof both new and existing structures and have the following characteristics:

- Adapt perfectly to any shape of substrate.

- Excellent bond to various types of substrate thanks to a complete range of primers for any type of material.

- Immediate waterproofing and set to foot traffic.

- Excellent tensile and tear strength.

- High static and dynamic crack-bridging capacity, including at low temperatures.

- Considerable elongation capacity.

- Excellent resistance to alkalis, diluted acids and detergents.

- No reinforcement required.

- Do not generate overloads on load-bearing structures.

- Thanks to the special finishes available, the colour of the membranes are unaffected by UV rays.

- All PURTOP membranes are marked CE (EN 1504-2).

The range of waterproofing membranes available are:

PURTOP 400 M: Waterproofing membrane for large flat roofs and bridge decks.

PURTOP 600: Thanks to its exceptional adhesion strength on a wide range of substrates, it is suitable for application on horizontal, sloping and curved surfaces not subject to traffic, on civil and industrial buildings.

PURTOP 1000: Waterproofing membrane for storage tanks, basins and hydraulic structures in general, as well as any structure requiring protection with a high-performance membrane.

PURTOP HA: Waterproofing membrane for small- to medium-size terraces and flat roofs, and for repairing surfaces waterproofed with hybrid polyurea and/or pure polyurea-based membranes.

PURTOP SYSTEMS

PURTOP SYSTEMS

As well as the spray-applied waterproofing membranes, Mapei also has three complete systems available for three specific types of waterproofing application.

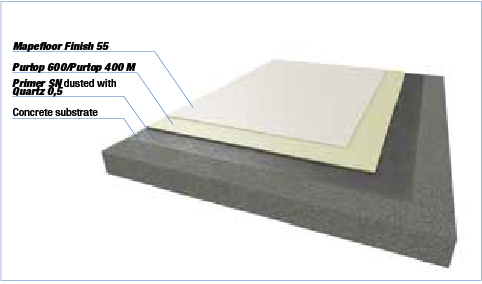

PURTOP System Roof

It is a spray-applied hybrid polyurea waterproofing system for non-trafficked roofs. It is made up of: PURTOP 600,

PURTOP 400 M,

PRIMER SN,

QUARTZ 0.25,

TRIBLOCK P,

PRIMER BI,

PRIMER EP RUSTOP,

PRIMER M,

QUARTZ 0.5, and

MAPEFLOOR FINISH 55.

It is mainly based on the use of PURTOP 600 and PURTOP 400 M and, thanks to the excellent crack-bridging capacity and resistance to stress of the membranes, this system is extremely versatile and suitable for numerous types of roof. It may be applied on various types of substrate: concrete, cementitious screeds, terrazzo, porcelain and klinker tiles, smooth and slated bitumen membranes and metallic structures.

To increase the membrane’s resistance to ultraviolet rays, aggressive chemicals and wear, MAPEFLOOR

FINISH 55 two-component, aliphatic polyurethane coating should be applied over the surface to give it an opaque, nonslip finish.

PURTOP System Tank

This is a spray-applied, pure polyurea-based waterproofing system for storage tanks, basins and hydraulic structures in general. It is made up of:

PURTOP 1000,

TRIBLOCK P,

PRIMER EP RUSTOP, and

PRIMER M.

It is mainly based on the use of PURTOP 1000. Thanks to its capacity to bond to various types of substrate and its rapid application procedure as well as its immediate waterproofing and set to foot properties, it is possible to repair the waterproofing capacity of various types of storage tanks and hydraulic structures in general, while the high mechanical strength and dynamic and static crack-bridging capacity of PURTOP 1000 make this system suitable for application on any type of substrate.

The high resistance to chemicals of the membrane also makes it suitable for contact with highly aggressive chemical substances.

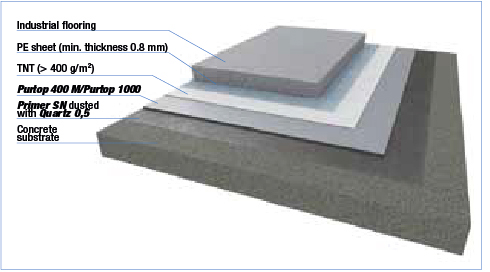

PURTOP System Deck

This is a

spray-applied hybrid polyurea or pure polyurea-based waterproofing system for trafficked roofs and bridges and viaduct decks. It is made up of:

PURTOP 400 M,

PURTOP 1000,

PRIMER SN,

QUARTZ 0.25,

MAPEFLOOR I 914,

TRIBLOCK P,

PRIMER M,

QUARTZ 0.5,

PURTOP PRIMER BLACK, and

QUARTZ 1.2.

It is mainly based on the use of PURTOP 400 M and PURTOP 1000. It is extremely versatile and suitable for numerous types of trafficked roofs, as well as trafficked surfaces typically found on many types of infrastructures. It may be applied on concrete in combination with various finishing products, on industrial flooring, self-locking blocks and asphalt.

This system may be used to repair the waterproofing capacity of various types of existing trafficked roofs and decks. Also, since PURTOP membranes are relatively thin, they do not generate overloads on load-bearing structures, and their excellent resistance to high temperatures means that asphalt may be poured directly on their surface.

A few examples of sites where this waterproofing membranes for rapid applications has been used are given below.

The Sewage Treatment Plant – Tiszaújváros

The sewage treatment plant of Tiszaújváros, in Hungary, was built in 1976 with an initial capacity of 3000 m

3/day. Due to the ever-increasing residential and industrial load, the capacity of the plant has become insufficient. Thus, it was high time for expansion and for renewal and waterproofing existing objects.

As a first step, tanks were drained off and concrete surfaces cleaned. The cleaning was followed by the application of a base coat layer: MAPEFLOOR H02, a two-component, solvent-free general epoxy primer.

Primer was applied in two layers: at applying the first base coat layer, smaller imperfections were filled with a mixture of MAPEFLOOR H02 and QUARZO 0.5, which resulted in a smooth finish. Then, the PURTOP 1000 pure polyurea waterproofing membrane was applied. Its thickness varied between 1.5 mm on vertical surfaces and 2.5 mm on the bottom of the basins and vaults. The total surface to be treated was 850 m

2 in each tank and the work took two days because of the divided surfaces.

The resulting construction joints were covered with PURTOP PRIMER OL so as to produce a 100 per cent waterproof layer throughout.

Former Jesuit Sports Centre – Pescara

The former Jesuit sports centre in Pescara, Italy, includes a football and a rugby pitch. The reinforced concrete terraces were deteriorating. After removing the seats and clamps, the surfaces were cleaned and sanded. Fillets were then made in all the 90° corners using MAPEGROUT LM2K two-component, fibre-reinforced mortar. The through joint between the base of the terraces and the asphalt surface were treated as a structural joint.

First, a strip of asphalt was removed from around the cracks to expose the underlying concrete slab. The slab was then cleaned and levelled off with MAPEGROUT LM2K and MAPEBAND TPE was applied by sandwiching the felt edges between two layers of ADESILEX PG4 epoxy adhesive applied. On the terraces was applied MAPEFLOOR I 914 epoxy primer, then dusted with QUARTZ 0.5 to help the waterproof membrane adhere.

After preparing the surfaces, a seamless layer of PURTOP 400 M two-component polyurea membrane was applied. The coloured finish was created by applying MAPEFLOOR FINISH 55 two-component, aliphatic polyurethane finish, dusted with QUARTZ 0.5 to create an antiskid support.

Nagarathar Sivan Temple Malaysia

The island of Penang, in Malaysia, known as the ‘Pearl of the Orient’, is a renowned tourist destination. Many of the Hindu temples on the island were founded by the Nattukottai Chettiar, the first Indian settlers in Malaysia. One of these temples is the Nagarathar Sivan, constructed more than 150 years ago.

The three roofs of the temple were starting to leak through cracks, which had formed following the previous restoration works about 10 years back. The proposed Mapei system comprised the application of PRIMER SN after the surfaces had been thoroughly cleaned, sprinkling quartz sand on the surface of the primer to enhance mechanical strengths, and then, spraying the surfaces with a coat of PURTOP 400 M two-components hybrid polyurea waterproofing membrane.

The cycle was completed by applying a coat of MAPEFLOOR FINISH 55 two-component polyurethane finish, which is highly resistant to UV rays and wear, and sealing the expansion joints with MAPEFLEX PU 45 polyurethane sealant.